Page 1 of 1

Wire Edging

Posted: Thu Feb 24, 2011 6:47 pm

by M Lightsey

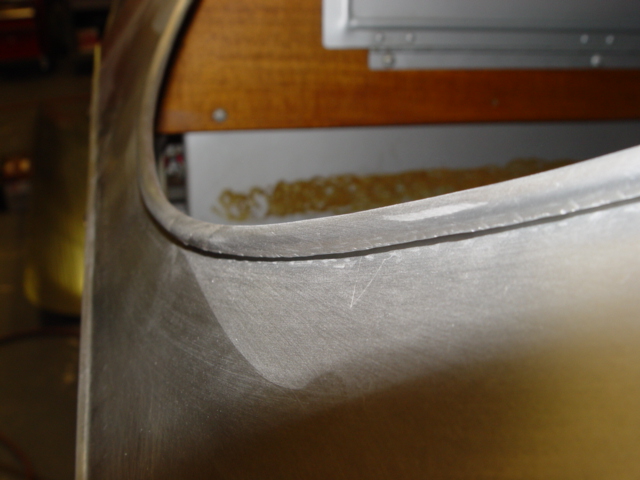

I was talking with Kevin this afternoon about finishing and reinforcing the edges of the cockpit sheetmetal and I dredged up these pictures that I took while restoring Bob Lock's CommandAire. Rather than just send them to Kevin, I thought I'd post them for anyone else who might find it helpful and while not a Hatz, the method is exactly the same. These first 3 shots show the edge being progressively tipped up to 90 degrees.

Mark

- DSC01308.JPG (129.72 KiB) Viewed 4025 times

- DSC01309.JPG (126.48 KiB) Viewed 4025 times

- DSC01311.JPG (140.31 KiB) Viewed 4025 times

Re: Wire Edging

Posted: Thu Feb 24, 2011 6:53 pm

by M Lightsey

Re: Wire Edging

Posted: Thu Feb 24, 2011 6:59 pm

by M Lightsey

Keep working it and use a pair of smooth pliers to tuck in the last little bit. Cover it with a length of 3/8" air hose following with some pipe insulating foam. You've got a reinforced cockpit opening that you can put some weight on that looks pretty cool even if you don't get around to installing the coaming for a while.

Mark

- DSC01316.JPG (133.46 KiB) Viewed 4024 times

- DSC01319.JPG (127.68 KiB) Viewed 4024 times

- DSC01322.JPG (134.36 KiB) Viewed 4024 times

Re: Wire Edging

Posted: Thu Feb 24, 2011 7:04 pm

by M Lightsey

Re: Wire Edging

Posted: Fri Feb 25, 2011 8:14 am

by alvinsager

Hi Mark,

Thanks for the post. Really nice work. I was wondering what alloy you used.

Al

Re: Wire Edging

Posted: Fri Feb 25, 2011 8:48 am

by dougm

Beautiful job! what is the width of the flange you are bending?