Page 2 of 3

Re: Lathe work

Posted: Mon Mar 26, 2018 11:24 am

by orchardair

Thanks all for your input.

I decided to try and tackle the lathe work myself, on a WW-II era Atlas lathe.

I started with the simpler (?) parts, the spring retainers for the gear legs, and was surprised by the success I had (and the minimal amount of blood I had to shed).

Here is what I did:

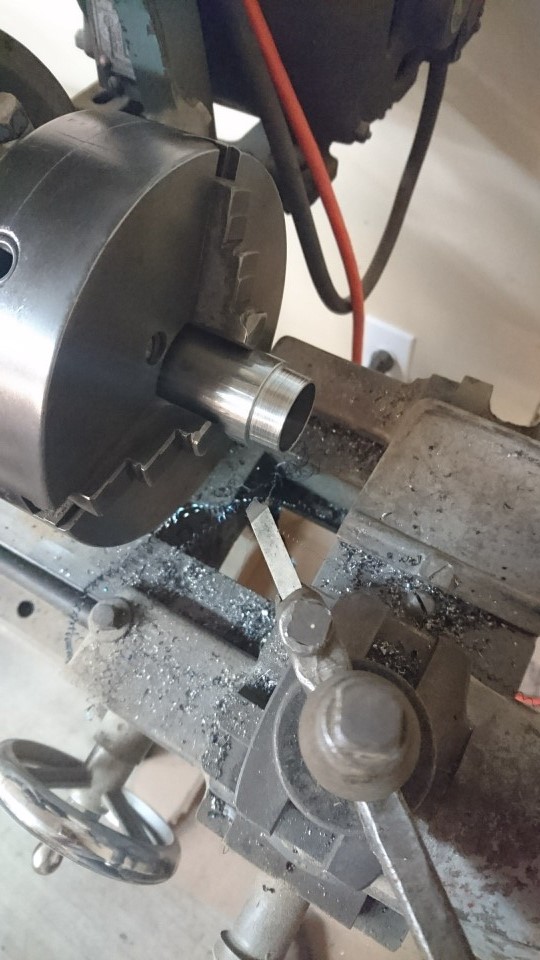

Step 1: Mark the stock for size (plus some extra) and drill the hole while the part is still easy to clamp. then enlarge the hole to 1/4":

- Drill before cutting.

- DSC_0001.jpg (130.51 KiB) Viewed 4543 times

Step 2:

Cut the part off:

- cut it

- DSC_0002.jpg (137.63 KiB) Viewed 4543 times

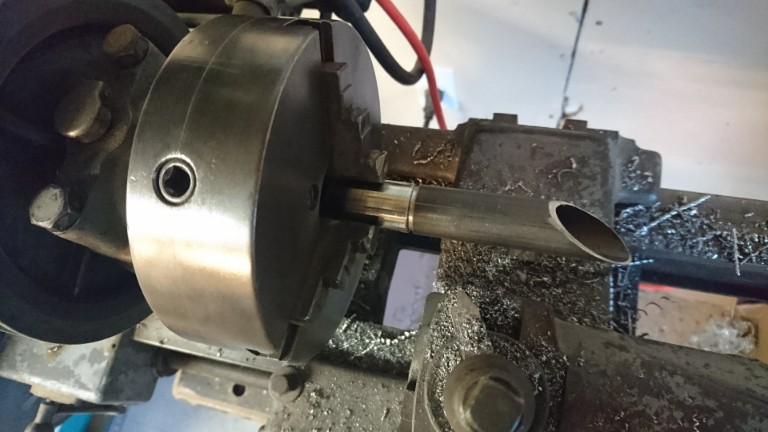

Step 3:

Enjoy lathing. I don't really know if this is the best way to do it, but it worked for me. I finished both ends to correct size, as I had a little bit of extra length when I cut the tube.

- lathe it

- DSC_0003.jpg (128.66 KiB) Viewed 4543 times

Step 4: Check for fit. Repeat 3 more times.

- DSC_0083.jpg (72.34 KiB) Viewed 4543 times

- DSC_0082_7.jpg (75.19 KiB) Viewed 4543 times

Re: Lathe work

Posted: Mon Mar 26, 2018 11:27 am

by orchardair

I also modified the aluminum fittings for the tank on the lathe, removing material from the outer end of the lip to make it flat:

- DSC_0012.jpg (118.91 KiB) Viewed 4543 times

Next, 30 little threaded tube-ends..

Re: Lathe work

Posted: Fri Mar 30, 2018 8:29 am

by HC85

Nice work doc! My cousin has an Atlas lathe, he loves that bugger!

Re: Lathe work

Posted: Tue Apr 24, 2018 1:48 pm

by orchardair

I am starting to get the hang of the lathe, still probably doing many things wrong, but I am now turning the threaded tube endings.

I figured I'd share the joy....

Step 1: Chop a piece off your 4130 rod.

- I used an angle grinder with a cut-off wheel.

- DSC_0040.jpg (87.65 KiB) Viewed 4439 times

Step 2: Square the end.

- The 1936 Atlas lathe

- DSC_0043.jpg (90.55 KiB) Viewed 4439 times

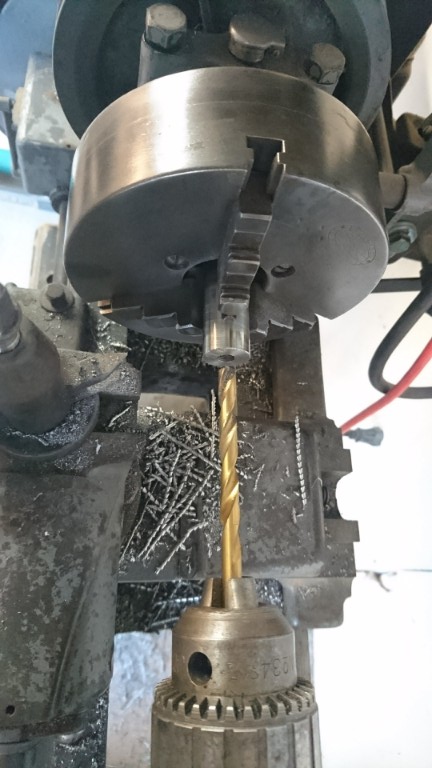

Step 3.a: Drill the hole for the tap (size I I think).

- first hole

- DSC_0045.jpg (93.73 KiB) Viewed 4439 times

Step 3.b: Drill the large hole (To reduce mass for the rosette weld).

- 5/8" drill, I believe.

- DSC_0046.jpg (86.5 KiB) Viewed 4439 times

Step 4: Reduce the radius of the outer dimension.

- reduce radius

- DSC_0047.jpg (83.49 KiB) Viewed 4439 times

(continued on next post)

Re: Lathe work

Posted: Tue Apr 24, 2018 1:50 pm

by orchardair

(continued)

Step 5: Test for fit

- Scrap tube for testing

- DSC_0048.jpg (73.03 KiB) Viewed 4439 times

Step 6: Cut off the other end

- cut off.

- DSC_0049.jpg (47.37 KiB) Viewed 4439 times

Repeat as many times as needed.

Not done yet: Tapping the hole.

Re: Lathe work

Posted: Mon Aug 13, 2018 10:10 am

by orchardair

Well, these took more time than I expected, but I have a full set now!

- full set

- DSC_0012 (1).jpg (68.52 KiB) Viewed 4212 times

I hope I counted correctly!

I figured since I have to hand-tap them, I'll do it after they are welded to the tubes.

Any tips on tapping will be appreciated!

Re: Lathe work

Posted: Tue Aug 14, 2018 5:52 am

by JBMoore

Do it in the lathe and chase the threads after you weld them.

Jeff Moore

Re: Lathe work

Posted: Tue Aug 14, 2018 7:38 am

by Bitshifter

I would tap them before welding and then chase them. Using the lathe would be the best since you will be assured that they are straight.

Re: Lathe work

Posted: Tue Aug 14, 2018 10:33 am

by orchardair

Thanks for the suggestion. I'll give it a try.

Re: Lathe work

Posted: Tue Aug 14, 2018 11:32 am

by Bitshifter

When I use the lathe I turn the turret by hand, I don't have the guts or coordination to do it powered.